I. Technical Definition and Core Characteristics

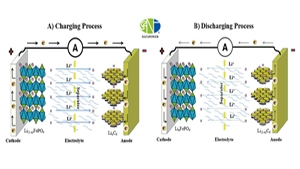

Lithium Polymer Batteries (Li-Po), developed from liquid lithium-ion battery technology, share the same cathode and anode materials as liquid batteries but utilize

gel electrolyte and

aluminum-plastic film packaging. This design delivers core advantages of

lightweight, high energy density, and high safety, gaining widespread recognition among global clients for Technical Analysis of Lithium Polymer Batteries.

| Model |

Dimensions (Thickness × Width × Height, mm) |

Nominal Capacity (mAh) |

Internal Resistance (mΩ, <) |

Nominal Voltage (V) |

| 3578131 |

3.5×78×131 |

4000 |

40 |

3.7 |

| 3463110 |

3.4×63×110 |

2700 |

40 |

3.7 |

| 3845120 |

3.8×45×120 |

2200 |

40 |

3.7 |

| 366090 |

3.6×60×90 |

2000 |

40 |

3.7 |

| 3435165 |

3.4×35×165 |

1800 |

40 |

3.7 |

| 2453135 |

2.4×53×135 |

1400 |

40 |

3.7 |

| 385085 |

3.8×50×85 |

1300 |

60 |

3.7 |

| 344461 |

3.4×44×61 |

1200 |

60 |

3.7 |

| 255480 |

2.5×52×80 |

1150 |

50 |

3.7 |

| 393278 |

3.9×32×78 |

1100 |

65 |

3.7 |

| 305060 |

3×50×60 |

900 |

40 |

3.7 |

| 383450 |

3.8×34×50 |

600 |

70 |

3.7 |

| 383450 |

3.8×34×50 |

450 |

80 |

3.7 |

| 233759 |

2.4×37×59 |

380 |

80 |

3.7 |

| 392339 |

3.9×23×39 |

330 |

80 |

3.7 |

| 302441 |

2.8×24×40.5 |

250 |

100 |

3.7 |

| 251776 |

2.5×17×76 |

230 |

120 |

3.7 |

| 302145 |

3×21×45 |

210 |

150 |

3.7 |

| 222530 |

2.5×25×30 |

120 |

180 |

3.7 |

| 321239 |

3.1×12×39 |

100 |

200 |

3.7 |

- Wound Type: Uses the same winding process as liquid lithium-ion batteries, winding cathode, anode, and electrolyte films, then packaging with aluminum foil. Suitable for large-scale production.

- Laminated Type: Uses hot-pressing technology to laminate cut cathode, anode, and electrolyte films, sealed with aluminum foil for higher structural flexibility.

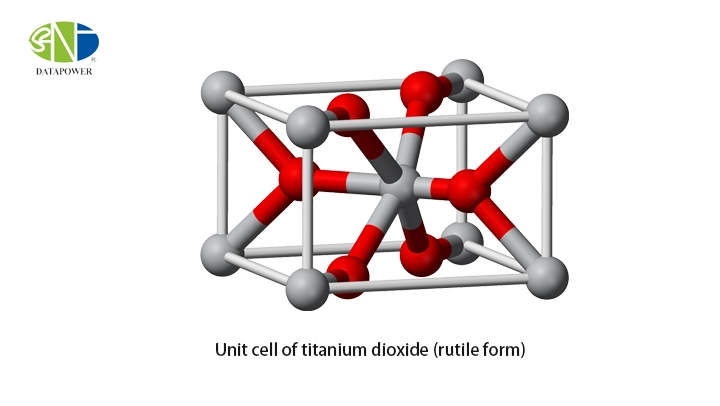

- Gel Polymer Electrolyte Battery (GPE-LiPo): Adds conductive additives to solid polymer electrolytes, achieving room-temperature ionic conductivity of 10⁻³ S/cm for ambient operation.

- Solid Polymer Electrolyte Battery (SPE-LiPo): Electrolyte is a polymer-salt composite with low room-temperature conductivity (10⁻⁶ S/cm), suitable for high-temperature environments (>60°C).

- Composite Gel Polymer Cathode Battery (CPE-LiPo): Employs conductive polymers as cathode materials, offering 3× the specific energy of conventional lithium-ion batteries—next-generation technology.

| Technical Index |

Performance |

| Safety |

No liquid electrolyte; aluminum-plastic film housing resists explosion. Thermal runaway temperature >200°C, reducing fire/explosion risk by 90%. |

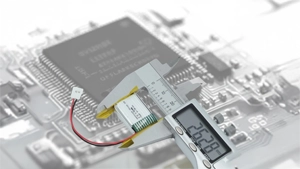

| Thinness |

6V/400mAh battery thickness down to 0.5mm, compatible with ultra-thin electronics. |

| Lightweight |

40% lighter than steel-cased Li-ion batteries, 20% lighter than aluminum-cased ones. Energy density increased by 15-20Wh/kg. |

| Sealing |

Solid gel electrolyte eliminates leakage risk, operating in -40°C~60°C wide temperature range. |

| Capacity Density |

10-15% higher capacity than steel-cased batteries, 5-10% higher than aluminum-cased ones. Typical value: 200-250mAh/cm³. |

| Internal Resistance |

Typical <35mΩ, supports >20C high-current discharge, power density 1500W/kg. |

| Structural Adaptability |

Customizable shapes (curved/ultra-thin/irregular) meet demands of wearables, drones, and other niche applications. |

- Voltage System

- Nominal Voltage: 3.7V (single cell)

- Charging Voltage: 4.1-5.0V (constant current/constant voltage charging)

- Discharge Cut-off Voltage: 2.8V, Storage Voltage: 3.7-3.8V

- Capacity Calculation

Empirical formula: Capacity (mAh) = Thickness (mm) × Width (mm) × Length (mm) × K (K=0.15-0.25mAh/mm³, adjusted by material system)

- Rate Characteristics

- Charge Rate: 0.5C-5C (1C = rated capacity current, e.g., 2A for 2000mAh battery)

- Discharge Rate: 1C-20C (continuous)/30C (peak), affected by internal resistance

- Operating Temperature: Charging 0-45°C, Discharging -20-60°C

- Storage Conditions: -20-35°C, humidity 45%-75%. Long-term storage requires 30-50% state of charge.

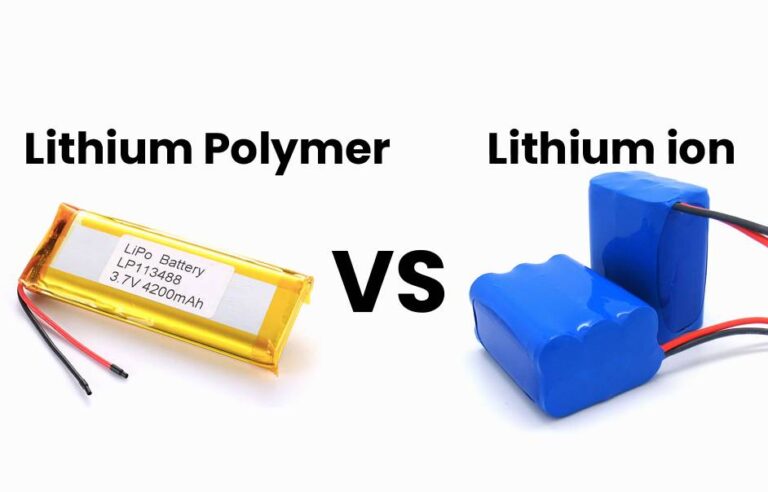

| Dimension |

Lithium Polymer Battery (Li-Po) |

Liquid Lithium-ion Battery (Li-ion) |

| Electrolyte Form |

Gel/solid, no flow risk |

Liquid organic electrolyte, requires rigid casing |

| Shape Adaptability |

Customizable (thickness <1mm) |

Cylindrical/rectangular, fixed shape |

| Energy Density |

200-250Wh/kg |

150-200Wh/kg |

| Safety |

Thermal runaway >200°C, no explosion risk |

Thermal runaway 150°C, requires protection circuit |

| Internal Resistance |

<50mΩ (typical) |

80-120mΩ |

| Production Cost |

High (complex aluminum-plastic film process) |

Low (mature steel/aluminum casing) |

| Cycle Life |

500-800 cycles (0.5C charge/discharge) |

300-500 cycles |

Integrates cells via series-parallel connection (e.g., 3S1P=3 cells in series, 1 parallel, nominal 11.1V), including:

- Battery Management System (BMS): Overcharge/over-discharge/overcurrent protection, supports Bluetooth communication.

- Connection System: Molex 2510/JST SHR connectors, supports 20-100A current.

- Structural Components: Insulating Highland barley paper layers, aluminum alloy frames (vibration-resistant).

- Consumer Electronics: Wearables (<2mm thickness), foldable smartphones (irregular batteries).

- Power Systems: Drones (25C discharge rate), power tools (40V series systems).

- Energy Storage: Portable power stations (100-500Wh), RV backup power.

- Encapsulation Defects: Aluminum-plastic film damage allows moisture ingress, causing electrolyte decomposition (H₂/O₂/CO₂).

- Process Contamination: Moisture >20ppm hydrolyzes LiPF₆ electrolyte, generating HF to corrode electrodes.

- Overcharge/Over-discharge: Charging >4.3V triggers lithium plating; discharging <2.5V ruptures SEI film.

- Mechanical Damage: >0.5mm dents may cause internal short circuits; pinprick test leakage >100mA.

- Charging Standards: Constant current 1C≤I≤5A, constant voltage 4.20±0.03V, automatic cutoff >45°C.

- Discharge Management: Cutoff voltage ≥2.75V, continuous current ≤2C, pulsed discharge ≤10C (<10s).

- Storage Requirements: Discharge to 3.7V at 0.5C before long-term storage; check self-discharge rate (<5%/month) every 3 months.

- Hazardous Substances: Cathode LiCoO₂ contains carcinogenic cobalt; LiPF₆ electrolyte hydrolyzes to fluoride.

- Degradability: Aluminum-plastic film recycling rate >90%; electrolytes require glovebox handling to avoid HF gas release.

- Physical Methods: Crushing and screening to separate aluminum/copper foil, recovery rate >95%.

- Chemical Methods: Acid-base dissolution to recover Li/Co/Ni, metal recovery >90%.

- Policy Regulations: EU Battery Regulation mandates lithium recovery ≥50% by 2024, rising to 90% by 2027.

-

Brand Certification: Prioritize products with UL 2580 (for EVs) and IEC 62619 (for energy storage) certifications.

-

Capacity Verification: Require 0.2C discharge capacity (≥95% of nominal) and 1C cycle life (>500 cycles) reports.

-

Protection Circuit: Confirm BMS has active balancing (voltage precision ±5mV) and overtemperature cutoff (>60°C).

-

Design Fit: Customize battery profiles per device space. Ultra-thin devices recommend <3mm thickness; power applications prioritize high discharge rates (>15C).