Part1:Key Considerations for Airsoft Battery

In the world of airsoft, although batteries are small, they play a pivotal role. They are like the “heart” of an airsoft gun, providing power and enabling it to function in various scenarios. Whether it’s in intense simulated battles or daily shooting practice, a airsoft battery with excellent performance can make your airsoft gun perform better.

Airsoft guns have unique and stringent requirements for batteries. High energy density is the primary consideration. It ensures that the battery can store more electrical energy within a limited volume and weight, providing lasting power support for the airsoft gun. This allows players to enjoy the battle without having to change batteries frequently during the game. Stable discharge performance is crucial as it guarantees a steady power output during the shooting process of the airsoft gun, avoiding shooting instability caused by voltage fluctuations and thus affecting shooting accuracy. In fierce battles, every shot matters, and stable discharge performance gives players the confidence to aim at targets and hit them with one shot.

Safety is of utmost importance. During the use of airsoft guns, they are inevitably subjected to external forces such as collisions and squeezes. Batteries must remain safe under these circumstances and not have leakage, explosion, or other dangerous situations. Lightweight is also a factor that cannot be ignored. An overly heavy battery will increase the overall weight of the airsoft gun, affecting the player’s handling experience. Especially in scenarios where long-term use or flexible movement is required, a lightweight battery enables players to operate the airsoft gun more easily and freely.

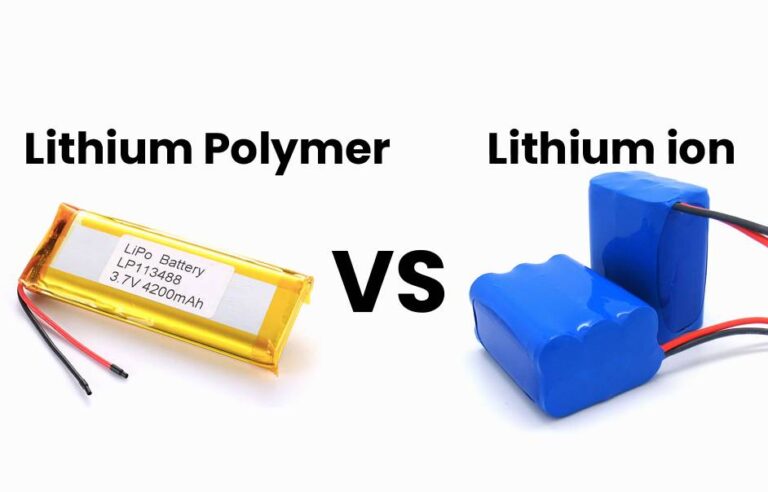

Lithium-ion polymer batteries, with their unique advantages, have become the ideal choice for airsoft gun batteries. They have relatively high energy density, which can meet the power and endurance requirements of airsoft guns. Their stable discharge characteristics can ensure the accuracy and stability of airsoft gun shooting. Their good safety allows players to use them without worry. And their lightweight design makes airsoft guns easier to carry and handle.

Part2:Demonstration of DTP Battery‘s Strength

(I) 15 Years of In-depth Cultivation and Quality Assurance

The 15-year manufacturing journey of lithium-ion polymer batteries by Data Power (DTP Battery)is a history of continuous progress and accumulation. Over these long years, DTP Battery have gradually developed from the initial exploration and attempts to become a leader in the industry. Every year, DTP battery invest a large amount of manpower and material resources in technological research, development, and improvement. In the selection of battery materials, DTP battery have conducted countless screenings and tests and finally determined raw material suppliers with stable performance and high safety. DTP battery have established long-term and close cooperative relationships with them. In terms of production processes, DTP battery have continuously optimized every step. From the production of electrode sheets to the assembly of batteries, each process strictly adheres to international standards to ensure the consistency and reliability of products. Through the accumulation of these 15 years of experience, DTP Battery have developed a keen insight into industry trends and can make forward-looking arrangements to develop new battery products that meet market demands. For example, DTP battery predicted that the market demand for miniaturized and lightweight batteries would continue to grow. So, DTP Battery increased our R&D efforts and successfully launched a series of lithium-ion polymer batteries suitable for various portable devices, which have been widely recognized and praised in the market.

(II) Professional Team and Innovation-driven

The company has an elite team composed of 25 professional product R&D engineers. They all graduated from well-known domestic and foreign universities in majors related to materials science and electrochemistry, possessing a solid theoretical foundation and rich practical experience. Among them, many engineers have worked in internationally renowned battery companies, participated in major battery R&D projects, and own multiple patented technologies. They have continuously explored and innovated in the field of lithium polymer batteries. They have achieved a major breakthrough in battery structure design and developed a new type of electrode structure, which effectively improves the energy density and charge-discharge efficiency of batteries. In terms of the battery management system, they have developed an intelligent management software that can monitor the battery status in real-time and extend the battery’s service life. With the efforts of these professionals, DTP Battery has always maintained a leading position in technology in the industry and led the development trend of lithium ion polymer batteries.

(III) Large-scale Production, High Efficiency, and High Quality

DTP Battery modern factory covers an area of more than 10,000 square meters and has over 500 employees, with a grand scale and advanced equipment. DTP Battey factory has introduced world-class automated production equipment. From the precise distribution of raw materials to the formation, inspection, and final packaging and shipment of batteries, every link has achieved intelligent and efficient production. In terms of production process management, DTP Battey have adopted an advanced ERP system to monitor and schedule the entire production process in real-time, ensuring the smooth implementation of production plans. Meanwhile, DTP Battey have established a strict quality inspection system. From the inspection of raw materials to the random inspection of finished products, each batch of products has to undergo multiple inspection processes, including performance inspection, safety inspection, and environmental adaptability inspection, to ensure that every battery leaving the DTP Battey factory meets high-quality standards. The powerful production scale and efficient production process enable us to meet the large-scale order requirements of customers and quickly respond to their customized needs, providing customers with high-quality products and services.

Part3:Unique Advantages of Products

(I) Safe and Worry-free for Use

Lithium ion polymer battery have an ingenious structural design, adopting aluminum-plastic soft packaging and abandoning the metal shells of traditional liquid cells. This aluminum-plastic soft packaging structure has good flexibility and deformability. When facing external impacts or internal pressure changes, it can effectively buffer and disperse energy, greatly reducing the risk of explosion. When abnormal situations occur inside the battery, such as excessive temperature or increased pressure, the aluminum-plastic soft packaging will expand first, forming a buffer space and avoiding instant explosions. In contrast, the metal shells of liquid cells are relatively hard and are prone to rupture under similar circumstances due to the sharp increase in internal pressure, which may then lead to serious consequences such as explosions.

In terms of electrolytes, lithium polymer batteries use colloidal electrolytes, which have higher stability compared to liquid electrolytes. Colloidal electrolytes are less likely to leak, reducing the safety hazards such as short circuits caused by electrolyte leakage. Even in extreme cases where the battery is squeezed or punctured, the colloidal electrolyte can maintain a relatively stable state and will not flow rapidly like liquid electrolytes and cause danger.

In addition, lithium polymer battery are equipped with an advanced battery management system (BMS). This system is like the “intelligent butler” of the battery, which can monitor parameters such as voltage, current, and temperature of the battery in real-time. When abnormal situations such as overcharging, or high temperature are detected, the BMS will quickly take corresponding protective measures, such as cutting off the circuit, to prevent the danger from further expanding, providing comprehensive protection for the safety of battery use. Whether in daily use or in complex and changing environments, lithium polymer battery allow users to use them with peace of mind without worrying about safety issues.

(II) Lightweight, Portable, and with Excellent Performance

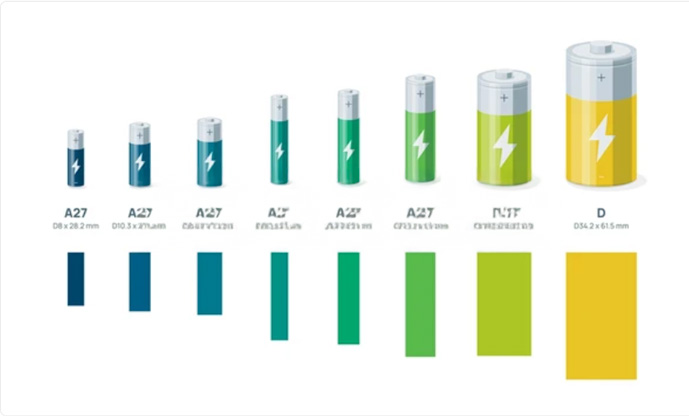

In terms of weight, polymer batteries (Lipo Batteries) show significant advantages. Compared to steel-shell lithium Cylindrical Battery of the same capacity specification, their weight can be reduced by about 40%. Compared to aluminum-shell 원형 배터리, they can also be 20% lighter. This lightweight feature is crucial for airsoft guns. During the use of airsoft guns, players need to frequently change postures and move positions. A lighter battery can significantly optimize the overall weight of the airsoft gun, making it more flexible and convenient for players to handle. Even after long-term use, players are less likely to feel tired, enabling them to react more quickly in battles and seize the initiative.

In terms of thickness, polymer Battery cells have broken through the limitations of traditional batteries. Ordinary liquid lithium ion batteries, due to the method of first customizing the shell and then inserting the positive and negative electrode materials, face technical bottlenecks when the thickness is below 3.6mm. However, polymer Batteries cells can easily reach below 1mm. This ultra-thin feature allows airsoft guns to have a more compact design, not only improving the portability of airsoft guns but also providing more space for optimizing their internal structures. For example, in some airsoft gun models with high space requirements, the space saved by using polymer batteries can be used to install other high-performance accessories, such as more accurate scopes or more efficient power devices, further enhancing the overall performance of the airsoft gun.

(III) Larger Capacity and Longer Endurance

Lithium polymer battery (Lipo Battery) have a relatively high energy density. Compared to steel-shell batteries of the same size specification, their capacity is 10 – 15% higher, and compared to aluminum-shell batteries, it is 5 – 10% higher. This means that under the same volume, polymer batteries can store more electrical energy and provide airsoft guns with longer endurance. In an intense simulated battle, airsoft guns using lithium ion polymer batteries can shoot continuously for a longer time, reducing the trouble of frequently changing batteries due to insufficient power and allowing players to fully immerse themselves in the battle without missing any crucial moments.

In addition to the large capacity advantage brought by high energy density, polymer battery (Li Po Battery) can also maintain stable performance under high discharge rates. When airsoft guns need to fire a large number of bullets instantaneously, the batteries can quickly provide powerful current support, ensuring that the shooting speed and power of the airsoft gun are not affected. This stable performance under high discharge rates enables airsoft guns to handle various battle scenarios with ease, whether it’s rapid continuous shooting or single-shot precise shooting, and reliable power support can be obtained.

(IV) Customization at Will and Strong Compatibility

Another significant advantage of polymer battery (Lipo Battery) lies in their customizability. They can flexibly increase or decrease the thickness of battery cells according to customer needs and develop new battery cell models. This customized service is of extremely high value in the airsoft gun field. Different models of airsoft guns have differences in internal space layout and battery compartment design. Polymer battery (Lipo Battery) can be customized according to these specific requirements to perfectly match various airsoft guns. For example, for some airsoft guns with unique shapes and narrow internal spaces, Polymer battery (Lipo Battery) can adjust the thickness and shape of the battery cells, make full use of the limited space, achieve seamless connection between the battery and the airsoft gun, not only improve the installation stability of the battery but also enhance the overall performance of the airsoft gun.

Part4:One-stop Service and the King of Cost-performance

As a source lithium Polymer battery factory, Data Power (dTP battery) provides one-stop battery solutions for customers and supports OEM and ODM services. We have a professional R&D team and advanced production equipment and can provide personalized services throughout the entire process from battery design, development to manufacturing according to the specific requirements of customers. During the customization process, we fully consider the needs and opinions of customers and maintain close communication with them to ensure that the final product meets their expectations. Whether it’s the performance parameters, external dimensions, or appearance markings of the battery, they can all be customized according to the requirements of customers. This one-stop solution not only saves time and costs for customers but also improves the quality and market competitiveness of products. Customers don’t need to worry about finding different suppliers. Data Power (dTP battery) can meet all their needs at one time and provide them with convenient, efficient, and high-quality services.

Data power (dTP battery) can achieve the best price, the best quality, and the best service due to multiple advantages. In terms of price, as a source factory, we eliminate many costs in the intermediate links and can supply products to customers in the most direct way, thus ensuring price competitiveness. Meanwhile, large-scale production and an efficient management model enable us to effectively control costs while ensuring product quality, further providing customers with favorable prices. In terms of quality, with 15 years of manufacturing experience, a professional R&D team, and a strict quality inspection system, every link from raw material procurement to finished product delivery is strictly controlled to ensure that every battery meets high-quality standards. In terms of service, we focus on customers and provide one-stop services. From pre-sale demand communication and solution design to in-sale production follow-up and quality monitoring, and then to after-sale technical support and problem-solving, there are professional teams providing services throughout the whole process to ensure that customers can experience high-quality and efficient service at every stage of cooperation with data Power (dTP battery).

Part5: Customer Cases and Testimonials

In the field of airsoft gun batteries, data Power (DTP Battery) has won the trust and support of many well-known airsoft gun brands and players with its outstanding product quality and excellent services.

A certain well-known airsoft gun brand A has adopted customized lithium polymer batteries from data power (DTP battery) in its high-end product series. The person in charge of the brand said, “The batteries of data power perform extremely well in terms of performance. The high energy density gives our airsoft guns a longer endurance time, and they can maintain a stable shooting speed and accuracy even in intense competitions. Their lightweight and portable characteristics also make the overall design of our airsoft guns more refined and improve their handling. Moreover, Data power‘s one-stop service has saved us a lot of time and energy in the product R&D process, enabling us to quickly launch new products to the market.”

A senior airsoft gun player B shared his usage experience, “I have used batteries of many brands for airsoft guns, but the batteries of data power have left a deep impression on me. Their safety makes me feel very relieved, and there have been no problems in various complex game environments. Last time, during an outdoor competition, my airsoft gun accidentally fell to the ground. I was worried that the battery would be damaged at that time. But after picking it up, I continued to use it, and everything was normal. Moreover, its capacity is indeed much larger than the batteries I used before. I didn’t need to change the battery throughout a competition, allowing me to fully immerse myself in the battle.”

These cases and testimonials fully demonstrate the strong influence and high customer satisfaction of data Power’s lithium polymer batteries in the airsoft gun market. We will continue to adhere to the concept of quality first and service first as always and provide better battery products and services for the vast number of airsoft enthusiasts.

Part6:Future Prospects

With the continuous progress and innovation of science and technology, the application prospects of lithium ion polymer batteries in the airsoft gun field will be even broader. In terms of technological breakthroughs, we can expect the emergence of airsoft battery materials with higher energy density, which will further enhance the airsoft battery‘s endurance and enable airsoft guns to be used for a longer time after a single charge. The charging speed of airsoft batteries is also expected to be significantly improved, reducing the waiting time for players to charge and allowing them to quickly get into the game. In addition, the safety and stability of airsoft battery will be further enhanced. By developing more advanced battery management systems and safety protection technologies, the risk of battery failures during use will be reduced, providing players with a more reliable usage experience.

In terms of application expansion, lithium polymer battery will not only continue to play an important role in the traditional airsoft gun field but may also expand to some emerging airsoft gun-related fields. For example, with the development of smart airsoft guns, airsoft batteries will provide power support and meet the power requirements of smart systems. In the field of competitive airsoft guns, high-performance lithium polymer battery will become one of the key factors for players to pursue excellent results and help them perform at their best in competitions.

data power will always closely follow the industry development trends, continuously increase R&D investment, and keep innovating. We will actively explore new battery technologies and materials, strive to improve the performance and quality of products to meet the growing needs of customers. We will also continue to adhere to the customer-centered approach, provide high-quality one-stop services, and work hand in hand with customers to jointly create a bright future in the field of airsoft gun batteries.