Electric vehicles (EVs) are becoming more common on the roads, and one of the key technologies that make them run smoothly is the lithium-ion battery. These batteries are not only efficient but also powerful enough to allow electric cars to travel long distances without needing to stop and recharge every few miles. In this article, we will explore how lithium-ion batteries work in electric vehicles and why they are considered the heart of these eco-friendly machines.

What Are Lithium-Ion Batteries?

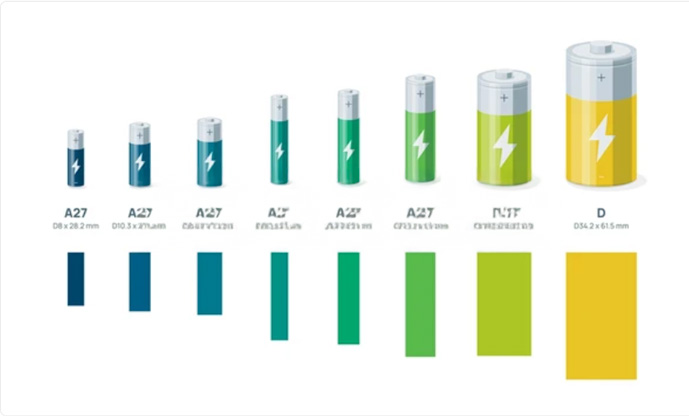

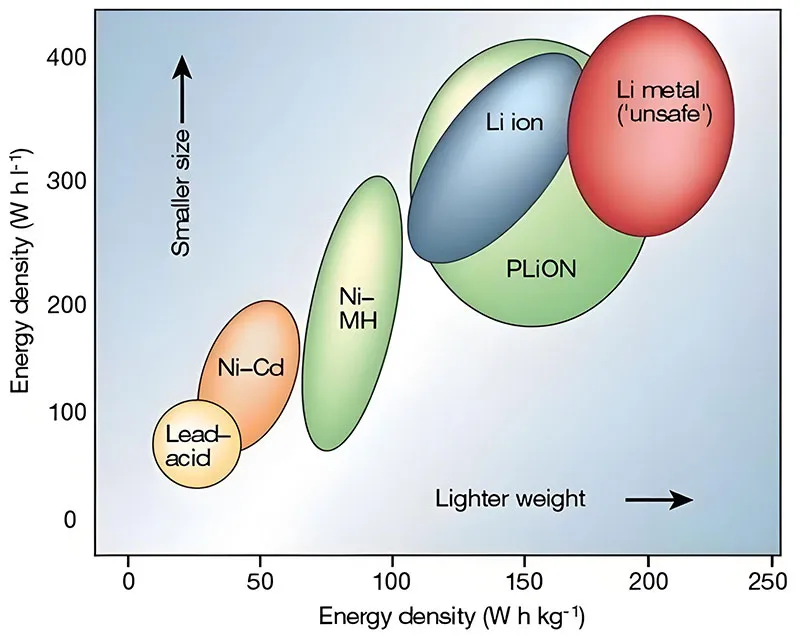

Lithium-ion batteries are rechargeable batteries that are commonly used in electronic devices such as laptops, smartphones, and, of course, electric vehicles. The reason why they are preferred over other types of batteries is due to their high energy density, lightweight, and ability to store large amounts of power in a compact space.

Basic Components of Lithium-Ion Batteries

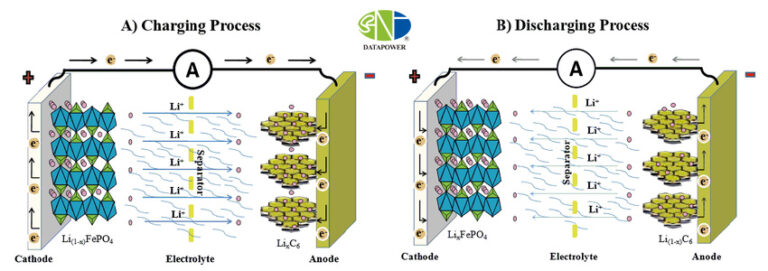

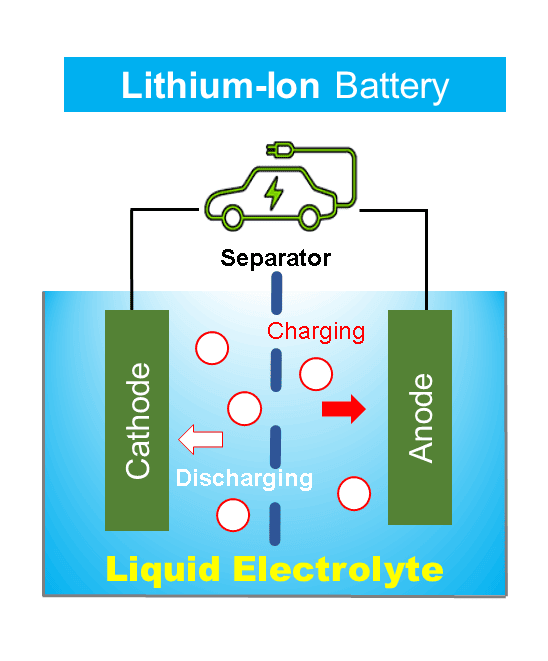

A lithium-ion battery consists of three main parts:

- Anode – This is usually made of graphite and stores lithium ions when the battery is charged.

- Cathode – This is typically made of lithium cobalt oxide or other lithium metal oxide materials. It releases lithium ions when the battery discharges.

- Electrolyte – A liquid or gel substance that allows the movement of ions between the anode and cathode.

How Do Lithium-Ion Batteries Work?

When a lithium-ion battery is charging, lithium ions move from the cathode to the anode. During discharge (when the battery is in use), the ions move in the opposite direction, from the anode back to the cathode, releasing energy that powers the vehicle. This flow of ions creates an electric current, which can be used to power the car’s electric motor.

Why Lithium-Ion Batteries Are Ideal for Electric Vehicles

1. High Energy Density

One of the biggest advantages of lithium-ion batteries is their high energy density. This means that they can store more energy in a smaller and lighter package compared to other types of batteries. This is crucial for electric vehicles, as they need to store a large amount of energy to allow the car to travel long distances without being too heavy.

For example, electric vehicles powered by lithium-ion batteries can easily travel several hundred kilometers on a single charge. This is a key factor in making electric vehicles a viable alternative to gasoline-powered cars, which rely on the energy stored in liquid fuels.

2. Long Cycle Life

Lithium-ion batteries can be charged and discharged many times before their performance starts to degrade. This is known as cycle life. Most lithium-ion batteries used in electric vehicles can last for over 1,000 charge cycles, and some high-quality batteries can last even longer.

This means that lithium-ion batteries have a long lifespan, which reduces the need for frequent replacements and makes them a cost-effective choice for powering electric vehicles.

3. Lightweight

Electric vehicles powered by lithium-ion batteries are lighter than those powered by other types of batteries, such as lead-acid or nickel-metal hydride (NiMH) batteries. This weight reduction is important for improving the efficiency and performance of electric vehicles, as a lighter vehicle requires less energy to move.

How Lithium-Ion Batteries Are Integrated into Electric Vehicles

Battery Pack Design

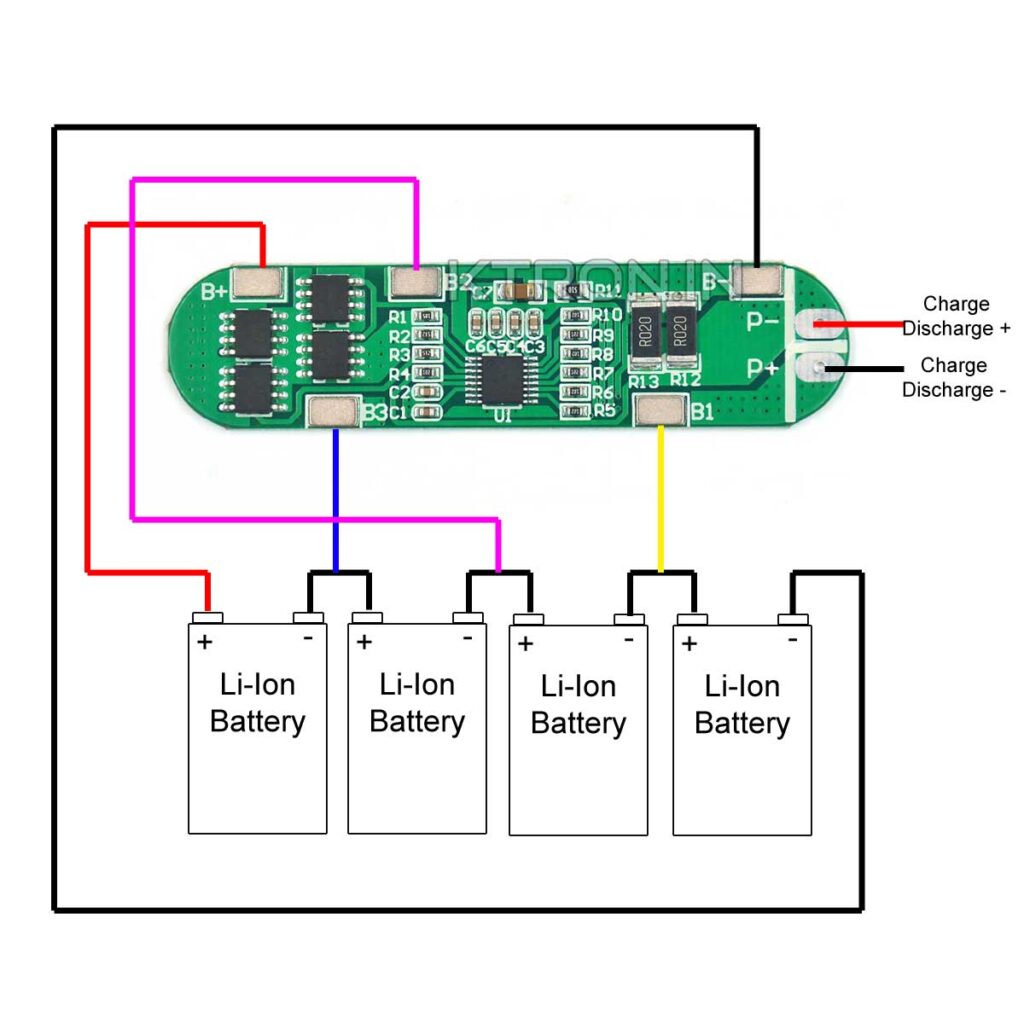

In an electric vehicle, a single lithium-ion cell is not enough to power the car. Instead, several cells are combined to form a battery pack. The battery pack is designed to provide the required voltage and capacity for the electric motor to function.

These battery packs are typically arranged in a series-parallel configuration, meaning that multiple cells are connected both in series (to increase voltage) and in parallel (to increase capacity).

Battery Management System (BMS)

The Battery Management System (BMS) is an essential component that ensures the safe and efficient operation of the lithium-ion battery pack. The BMS is responsible for monitoring the state of the battery, including its charge level, temperature, and voltage. It also ensures that the cells are balanced, meaning that all cells in the pack charge and discharge at the same rate to prevent damage and prolong battery life.

Thermal Management

Lithium-ion batteries generate heat during charging and discharging, so they need a thermal management system to keep them cool. Overheating can cause the battery to degrade faster or even fail, so manufacturers use cooling systems to regulate the temperature.

Some electric vehicles use liquid cooling, where coolant flows through pipes around the battery pack, while others use air cooling, where fans blow air over the cells to keep them cool.

How Long Can a Lithium-Ion Battery Last in an Electric Vehicle?

The lifespan of a lithium-ion battery in an electric vehicle depends on various factors, including the quality of the battery, how often it is charged, and how it is used. On average, lithium-ion batteries in electric vehicles last between 8 to 15 years, with most batteries retaining around 70-80% of their original capacity after 8-10 years.

It is also important to note that the battery’s performance can be affected by factors like extreme temperatures, charging habits, and how often the car is driven.

Environmental Impact of Lithium-Ion Batteries

Recycling and Sustainability

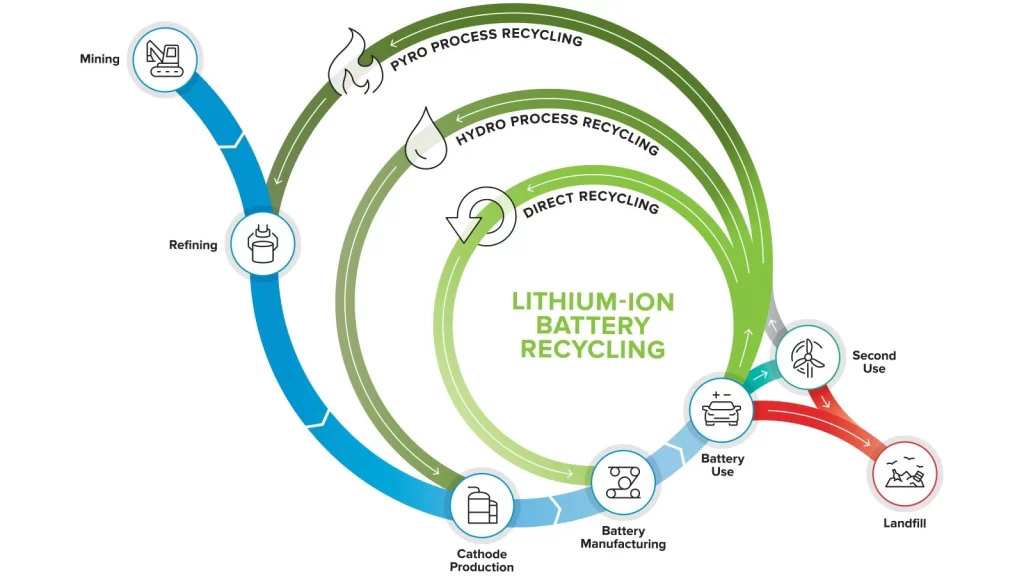

As electric vehicles powered by lithium-ion batteries become more common, the question of sustainability and recycling becomes more important. While lithium-ion batteries can be recycled, the process is still complex and not as widespread as it should be. However, advancements in recycling technology are being made, and more and more batteries are being recovered and reused.

Additionally, lithium-ion batteries have a much smaller environmental footprint compared to traditional combustion engine vehicles, as they produce fewer emissions during their use phase.

Raw Material Sourcing

The main materials used in lithium-ion batteries are lithium, cobalt, and nickel. Mining these materials can have environmental and ethical concerns, such as habitat destruction and poor working conditions in some countries. As the demand for electric vehicles grows, there is a push for more sustainable and ethical mining practices, as well as the development of alternatives to these materials.

The Future of Lithium-Ion Batteries in Electric Vehicles

As the demand for electric vehicles continues to rise, so does the need for better and more efficient batteries. In the future, we can expect lithium-ion batteries to continue improving in several areas:

1. Higher Energy Density

Researchers are working on improving the energy density of lithium-ion batteries. With higher energy density, electric vehicles can travel longer distances on a single charge, reducing range anxiety for drivers.

2. Faster Charging

One of the biggest limitations of lithium-ion batteries today is the time it takes to recharge them. While fast-charging stations are becoming more common, it still takes longer to recharge an electric vehicle compared to refueling a gasoline car. In the future, we may see lithium-ion batteries that can charge more quickly, making electric vehicles more convenient for daily use.

3. Lower Costs

The cost of lithium-ion batteries has been decreasing steadily over the past decade, and this trend is expected to continue. As the cost of production decreases, the price of electric vehicles will also come down, making them more affordable for consumers.