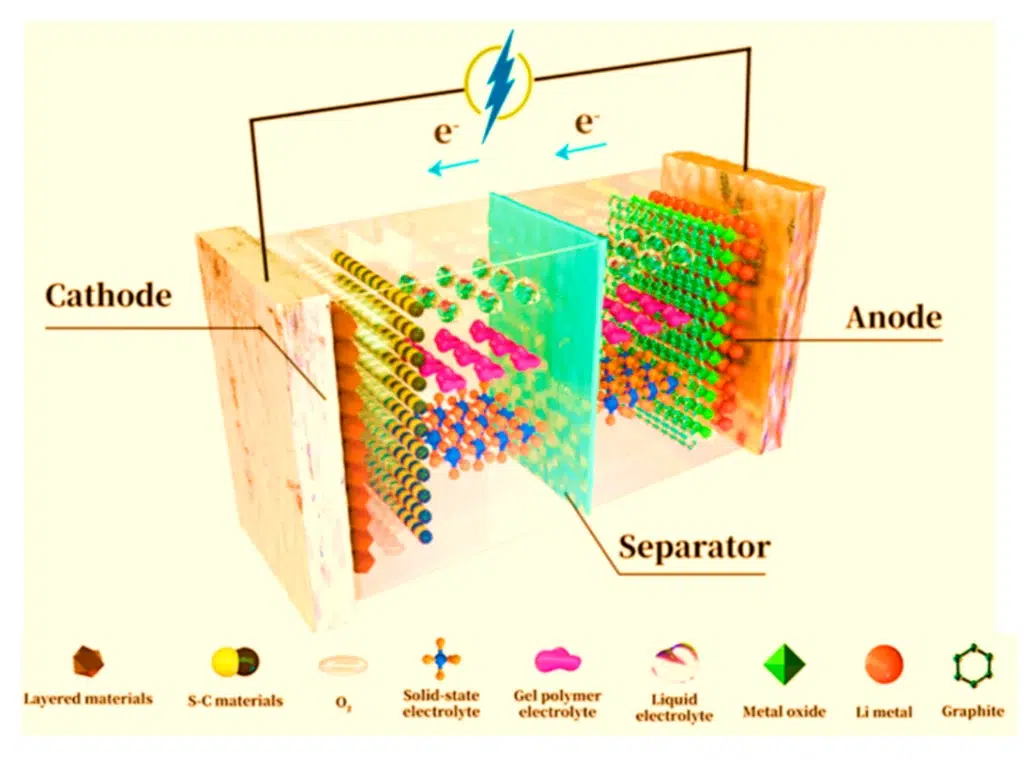

In today’s increasingly electrified world, the runtime of rechargeable batteries has become a critical consideration for both consumers and businesses. With applications ranging from portable electronics to electric vehicles, understanding how to optimize battery runtime can significantly impact operational efficiency and cost-effectiveness. This comprehensive guide explores the key factors affecting lithium battery runtime and provides practical solutions for maximizing battery performance.

Part1: Factors Affecting Battery Runtime

Several critical factors determine the runtime of lithium batteries. Battery capacity, measured in watt-hours (Wh) or milliamp-hours (mAh), serves as the foundation of runtime performance. According to industry data, high-capacity lithium iron phosphate (LiFePO4) batteries can achieve 2000-6000 charge cycles, while typical lithium-ion batteries range from 500-2000 cycles. Environmental conditions play a crucial role, with optimal performance typically occurring between -20°C to 55°C. Device power requirements and usage patterns also significantly impact runtime, with higher power draws naturally leading to shorter operation times.

Part2: Runtime by Battery Type

Different lithium battery chemistries offer varying runtime characteristics. LiFePO4 batteries, with their stable 3.2-3.7V operating range, provide consistent runtime performance and excel in long-term applications. Three-element (NCM) batteries, operating at 2.5-4.6V, deliver higher energy density but typically offer 800-2000 cycles. For smartphone applications, modern lithium batteries provide 130-220 mAh/g specific capacity, while electric vehicle applications benefit from LiFePO4’s superior safety profile and longer cycle life.

Part3: Tips to Maximize Battery Runtime

Implementing proper charging practices is essential for optimizing battery runtime. For lithium batteries, maintaining temperatures within the recommended range and avoiding extreme discharge conditions can significantly extend operational life. Data shows that LiFePO4 batteries maintain stable performance up to 75°C, while other lithium chemistries may experience rapid degradation above 50°C. Regular monitoring of battery health indicators and implementing smart charging solutions can help maintain optimal performance.

Part4: Battery Maintenance

Proper maintenance is crucial for maximizing battery lifespan and runtime. Regular inspection of battery parameters, including voltage levels and charging patterns, helps identify early signs of degradation. For industrial applications, implementing battery management systems (BMS) with features like temperature monitoring and cell balancing can significantly extend battery life. The documents indicate that advanced BMS solutions supporting precise capacity monitoring and cell temperature detection offer superior protection compared to basic hardware solutions.

Part5: Technical Specifications

Modern lithium batteries offer impressive specifications that directly impact runtime. LiFePO4 batteries provide 130-160 Wh/kg energy density, while NCM batteries achieve 180-240 Wh/kg. The choice between these technologies often depends on specific application requirements, with factors like safety, cycle life, and environmental conditions playing crucial roles in the selection process. The data shows that LiFePO4 batteries excel in large-scale energy storage applications, while NCM batteries are preferred for portable electronics requiring higher energy density.

As we look toward 2025, understanding and optimizing battery runtime becomes increasingly critical for businesses and consumers alike. The choice of battery chemistry, implementation of proper maintenance procedures, and adherence to best practices in battery management all contribute to achieving optimal runtime performance. For procurement professionals, considering factors like cycle life, operating temperature range, and safety characteristics is essential when selecting battery solutions for specific applications. By following the guidelines outlined in this article and staying informed about technological advancements, organizations can make informed decisions that maximize their battery investments.